Efficient oil separators in class 1 and 2 for both outdoor and indoor use

The separators are made of high quality and are adapted for workshops to larger washing facilities or car parks. Regardless of whether you are looking for a large or small oil separator, we have several variants in our range.

What are the differences between class 1 and 2?

The differences between class 1 and 2 oil separators are mainly related to their performance and efficiency. Class 1 has a higher purification capacity and is more suitable for smaller flows as the maximum emission level is 5 mg/l. Class 2 is instead more suitable for higher flows, even though its maximum emission content is higher at 100 mg/l. The type of oil separator that is most suitable depends on the size of the application, the capacity and the required cleaning performance requirements.

Complete systems for various areas of use

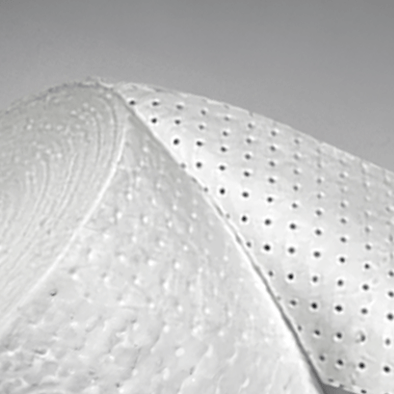

All separators supplied include everything for a complete approved system such as coalescence filter and automatic shut-off float. The wax-like surface on the inside makes emptying and cleaning very easy. Our class 1 and 2 oil separators are supplied complete including telescopic extension necks and covers.

Our oil separators are used in industry, but are also suitable for:

- Garage

- Laundry hall

- Workshop

- Car wash

- Industry

- Parking areas

How does an oil separator work?

Oil separators work by preventing unwanted substances, such as oil or petrol, from spreading into waste and storm water. The facility usually consists of a container and sludge separator, where the water can be led out and further through a drain. It should be used in operations where there is a risk that oil or other contaminated liquid may spread to the stormwater network.

When is an oil separator required?

Industrial sites and facilities that handle oils, chemicals or other pollutants have requirements for oil separators to minimize emissions and protect the environment. This is particularly relevant at gas stations, car washes, workshops, parking garages and similar types of businesses.

Care & emptying

Regular maintenance is important to ensure the efficient functioning of the oil separator and prevent pollution in the environment. In addition, it is important to follow local regulations and guidelines for waste management and report any leaks or deviations.

According to standard EN-858, an oil separator does not need to be vented, but this is required by the Swedish Housing Agency's building regulations and most municipalities. The ventilation line is drilled up and connected with a waterproof rubber grommet at the designated location.

You should also empty your oil separator at regular intervals. This is to ensure that it functions correctly, but also to comply with the legislation that requires the facility to be maintained and checked continuously. The emptying must then be documented and saved for at least two years. Do you have questions or concerns? You are welcome to contact us at for personal advice.

At what height should the alarms hang in the oil separator?

After the oil separator has been filled with water, the level sensor should hang so that 150 mm of the sensor protrudes into the water. The overflow sensor must hang 100 mm above the inlet pipe. Suspension is done via a standard hook suspension or directly in the grommet. You place holes for the cable entry where it fits best in the upper part of the separator. For waterproof cable entry, see article KE-917822.

How do I connect the sensors to the alarm unit?

The sensors are delivered with 1 cable and two conductors. For the level sensor, conductor 1 must be connected to terminal K3 – G. Conductor 2 must be connected to terminal K3 – 1. For the overflow sensor, conductor 1 must be connected to terminal K3 – G. Conductor 2 must be connected to terminal K3 – 2. About the sensor cable need to be spliced, it must be completely waterproof.

It says "Sensor error" in the display on the alarm unit, why?

This can be due to two reasons. Reason 1 is that the conductors in the cable to the sensors are connected incorrectly. See question "How do I connect the sensors to the alarm unit". Cause 2 is that a sensor that does not exist is activated. Hold down the "Reset" and "left arrow" buttons at the same time for 3 seconds. Enter the "inputs" menu and deactivate the sensors that do not exist.

Contact us for more information

Email: support@flexsell.se

Phone: 010-4500300