Flexsell Long-Term Grease LS 400g – High-Performance Long-Term Grease

Short product text

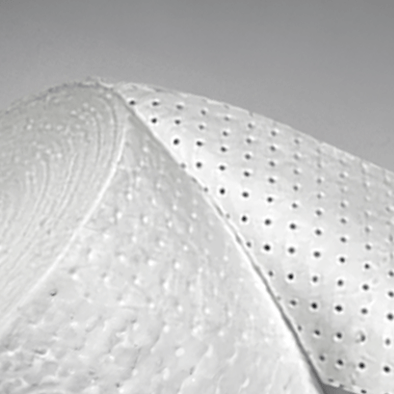

Flexsell Long-Term Grease LS 400g is a durable and versatile grease that provides long-lasting protection against wear, water and corrosion. Perfect for vehicles, industrial machinery and construction equipment operating under tough conditions.

Description

Flexsell Long-Term Grease LS 400g is a high-quality lubricating grease developed for rolling and plain bearings. It is made from first-class base oils with lithium soaps as thickeners, which provides exceptional oxidation resistance. The grease is water-repellent, highly adhesive, pressure-resistant and provides effective corrosion protection. Thanks to its high working strength, excellent wear resistance and strong adhesion properties, it is particularly suitable for lubrication under demanding operating conditions and in highly loaded bearings.

Practical benefits

-

Universal long-term grease for vehicles, industrial machinery and construction machinery

-

High resistance to water and corrosion

-

Very good adhesion and pressure resistance

-

Suitable for construction, stone and earthmoving machinery

Technical specifications

| Property |

Value |

Standard |

| Appearance |

Smooth, transparent, long-fibered |

– |

| Paint |

Blue |

– |

| Working temperature |

-30 °C to +120 °C (short-term up to +140 °C) |

DIN 51 825 |

| Dropping point |

+185 °C |

DIN ISO 2176 |

| Work penetration |

265 – 295 (0.1mm) |

DIN ISO 2137 |

| Decrease in penetration after 10,000 double strokes |

< 15 (1/10 mm) |

DIN ISO 2137 |

| Decrease in penetration after 100,000 double strokes |

< 25 (1/10 mm) |

DIN ISO 2137 |

| NLGI grade |

2 |

DIN 51 818 |

| Timken load |

55 lbs |

ASTM D2509 |

| Water resistance (5 h / +90 °C) |

Class 1 |

DIN 51 807-1 |

| Corrosion protection (Emcor test) |

Class 0 |

DIN 51 802 |

| Oxidation stability (100 h / 99 °C) |

< 0.3 bar |

DIN 51 808 |

| Base oil viscosity at 40 °C |

266.0 mm²/s |

DIN 51 562 |

| Base oil viscosity at 100 °C |

18.0 mm²/s |

DIN 51 562 |

| Four-piece welding load |

2,600 N |

DIN 51 350 |

| Designation |

KP 2 K-30 |

DIN 51 502 |